When mining feels the heat

Certain ores require pyroprocessing at high temperatures to liberate the valuable material and unlock its economic value. For example, sulphide ores bearing zinc, copper, and lead must be roasted at temperatures between 500°C and 1000°C to release the metal. Calcining bauxite during alumina production requires temperatures up to 1100°C, while in smelting and refining, the temperature can reach over 1200°C. Generating these temperatures is an energy-intensive business with a significant carbon footprint.

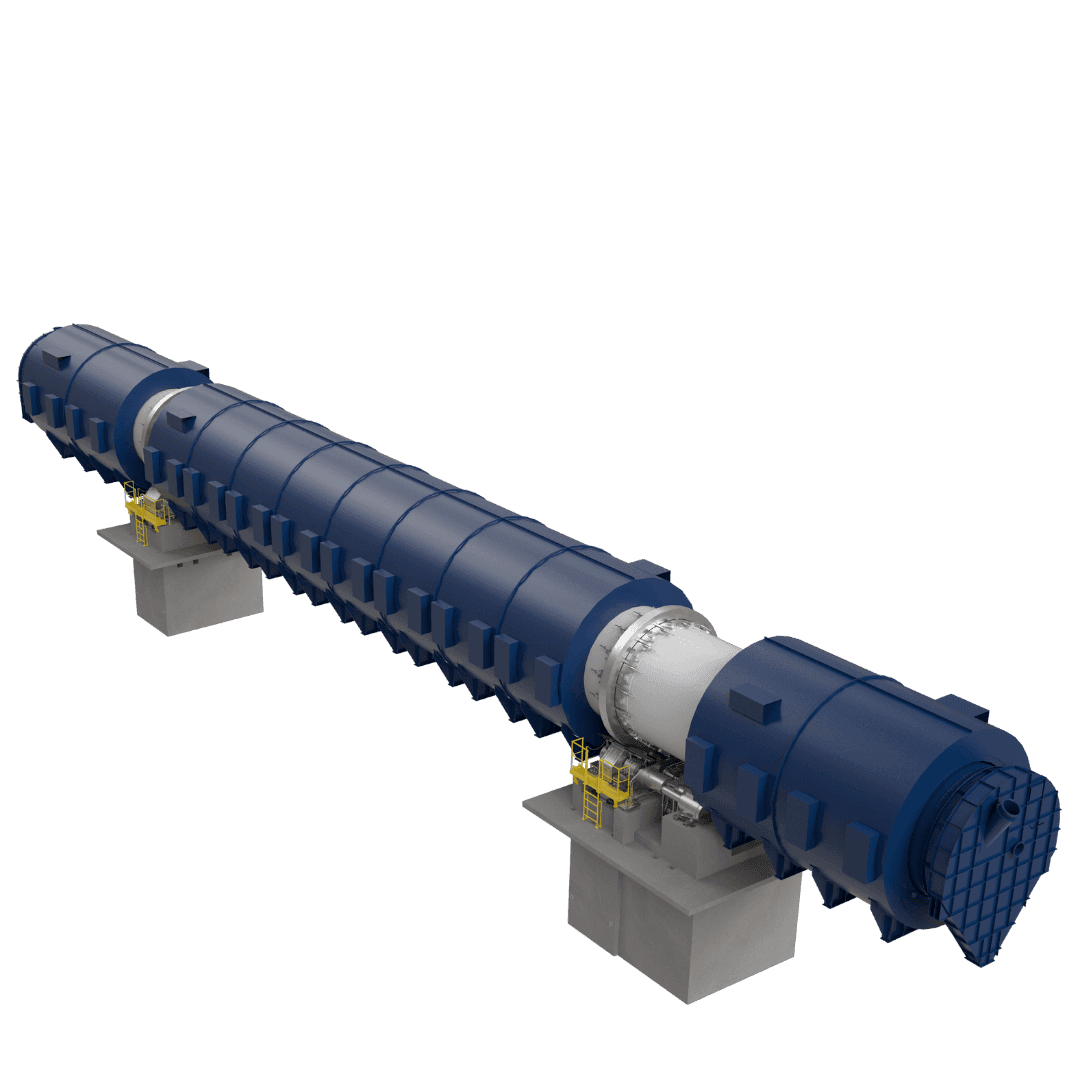

In a world of rising critical mineral demand and sensitivity to greenhouse gas emissions, this places pressure on pyroprocessing systems to deliver the output needed more efficiently and with lower emissions by reducing consumption of fossil fuels (and, where possible, replacing them with clean alternatives). Building on pyroprocessing experience spanning more than 140 years - with over 1000 rotary kiln systems supplied - FLS is at the forefront of these efforts.