Increase grade and recovery

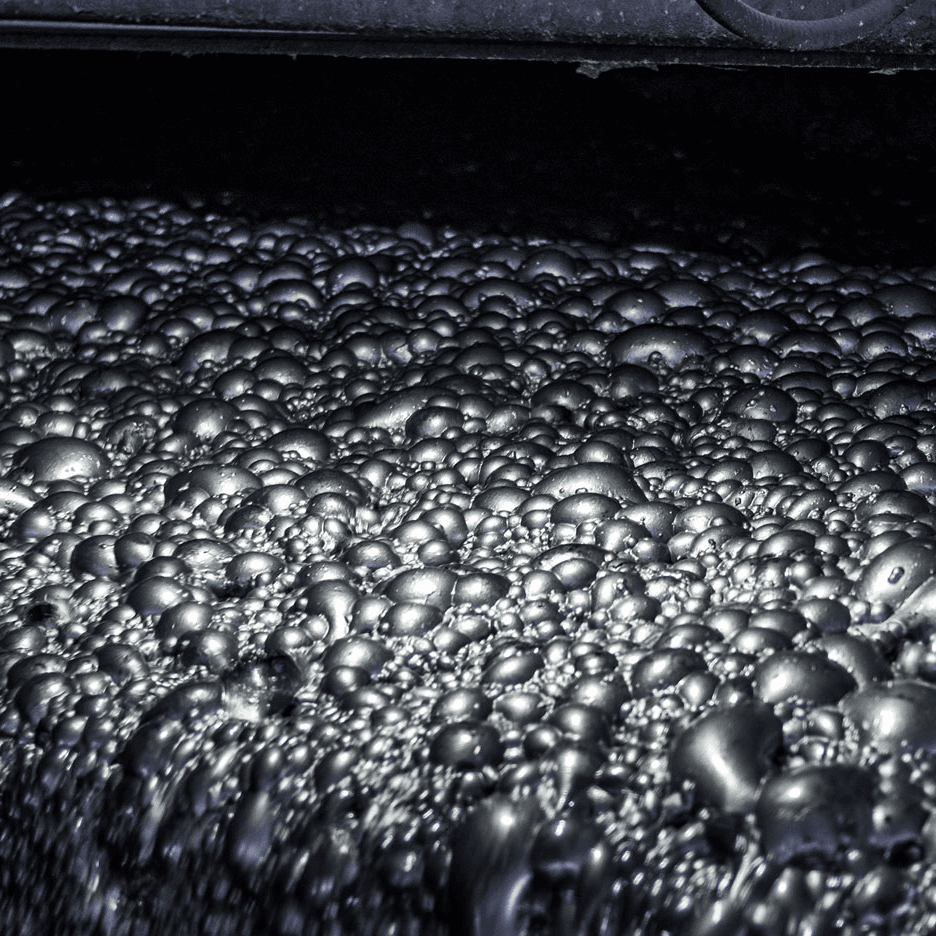

All our flotation upgrades are engineered to improve material recovery and grade, so you can get more from your ore.

All our flotation upgrades are engineered to improve material recovery and grade, so you can get more from your ore.

Our nextSTEP™ Rotor/Stator upgrade enables you to reduce the power requirement of your forced air flotation system by 15 – 40%, the lowest power energy flotation mechanism on the market. It can be retrofitted to any existing FLS forced air flotation systems and will provide longer wear life and up to 5% more material recovery alongside the energy benefits.

With our exchange programme, you can exchange worn flotation mechanisms for as-new components with a very short turnaround, enabling you to resume normal operations quickly and easily. No waiting for repairs or long lead times for new components – simply plan the exchange into your maintenance programme and we’ll refurbish the old mechanism while you’re using the new one.

Call in our process experts to inspect your flotation cells and we’ll provide an audit and study comparing current operating conditions with expected performance. This enables us to identify where the system is losing performance – the performance gap – and how this could be solved.

Depending on your performance targets, we will recommend an upgrade that suits your application. Our WEMCO II upgrade is available as an easy retrofit to all WEMCO flotation cells and provides immediate results including improved kinetics, better hydrodynamics and circulation, improved surface and froth stability, as well as the ability to control air without an external air supply.

In FLS and Dorr-Oliver® forced air flotation cells, the nextSTEP Rotor is designed to produce ideal flow streams. It also produces strong enough turbulence to enhance bubble-particle attachment. Meanwhile, the nextSTEP Stator dramatically improves attachment rates, which translates into statistically significant recovery increases.

Additionally, our add-on packages Froth Crowders, Radial Launders, and Froth Recovery can be added to both forced-air and self-aspirated flotation cells.

Furthermore, it may also be possible to upgrade third-party flotation cells, subject to review.

When your flotation mechanisms wear out, you don’t have to buy new – worn flotation mechanisms can be rebuilt to as-new condition in our fully fitted workshops and returned to you for reuse. Rebuilding gives you the reassurance of an OEM quality part without the cost of investing in new components. And, by reducing waste, you’re also benefitting the environment. Rebuilds are performed on a like-to-like basis bringing machines back to OEM specifications, extending operating life and improving reliability.

Take rebuilding to the next level by participating in our exchange programme. Exchanges provide all the benefits of rebuilding with the added bonus of inventory management – we'll deliver the as-new mechanism to you in a timely manner and remove your worn mechanism for rebuilding. Exchange programmes help close the loop on mechanical parts and give you the reassurance that you’ll always have access to the component you need.