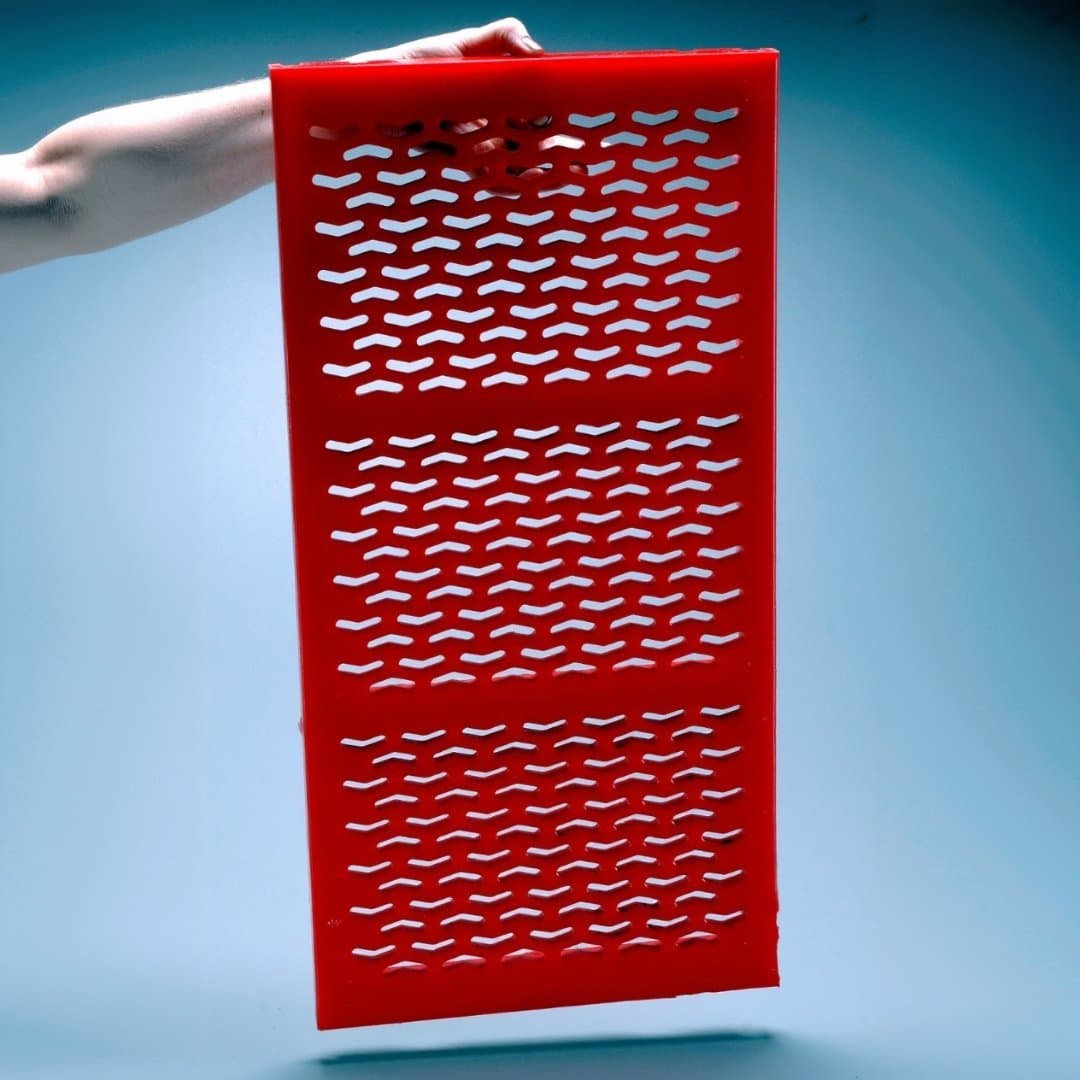

In mining operations, screening is a crucial step in material handling. It involves separating particles based on size, which directly impacts how efficiently the material is processed in subsequent stages. The performance of screening equipment heavily relies on the quality of screen media, which acts as the filter for this separation process. However, just like any other component in the mining flowsheet, screen media must be optimised to achieve peak efficiency.

Let’s explore how optimising screen media can improve separation efficiency, increase throughput, and what key considerations need to be taken into account to ensure the best performance.