The challenge: Overcoming mechanical roadblocks

SGM faced several serious technical issues with their 1400 x 2100 TS Gyro crusher that threatened to halt production. The primary problems included:

- Structural damage: Two of the four foundation bolts holding the massive machine in place were broken.

- Part failures: The countershaft was failing prematurely, and a crack had formed in the main hub of the bottom shell.

- Wear and tear: The existing spider shields did not cover all areas, leading to fast wear on expensive components.

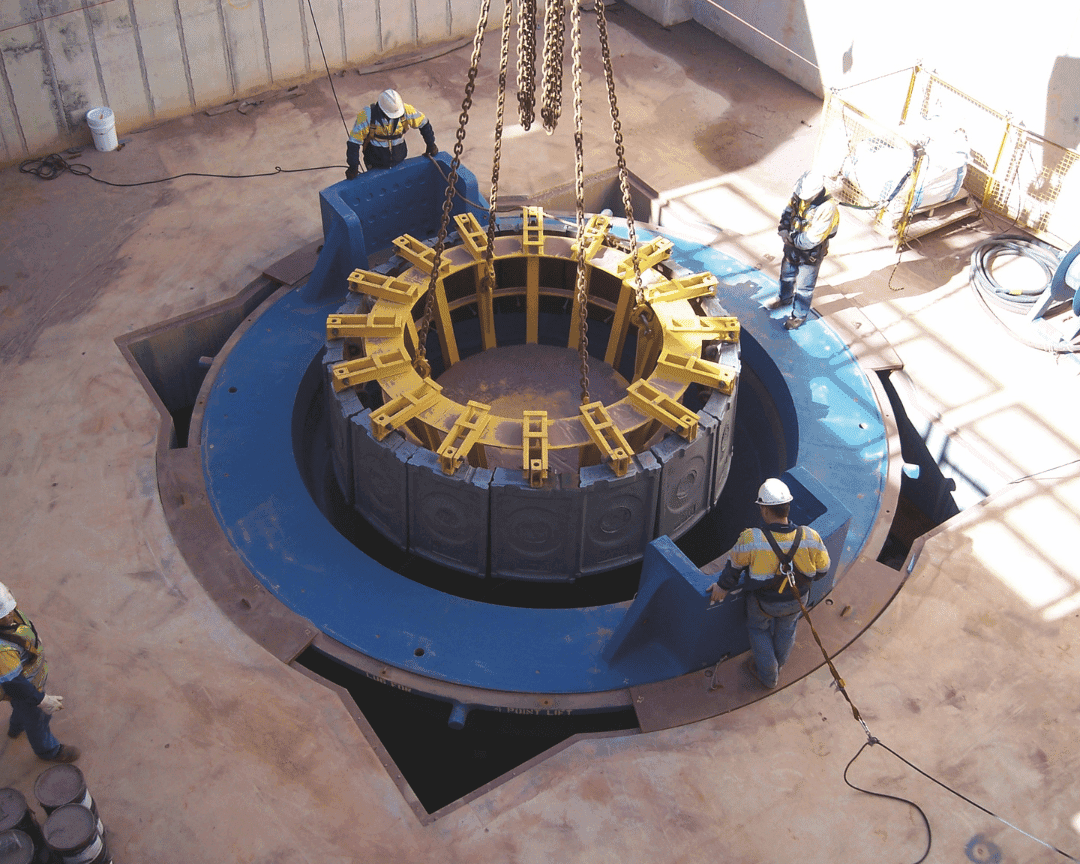

Centamin decided to replace the bottom shell rather than repair it to ensure future reliability. As the Original Equipment Manufacturer (OEM), FLS was the natural partner to lead this complex upgrade.